In the bustling environment of high-volume kitchens, efficiency and quality are paramount. These kitchens, often found in restaurants, hotels, and catering services, rely heavily on equipment that can withstand rigorous use while delivering consistent results. Among such equipment, deep fryers play a crucial role in preparing a wide array of dishes ranging from crispy fries to succulent fried chicken. However, maintaining these fryers goes beyond just cleaning; it involves meticulous oil management through effective filtration systems.

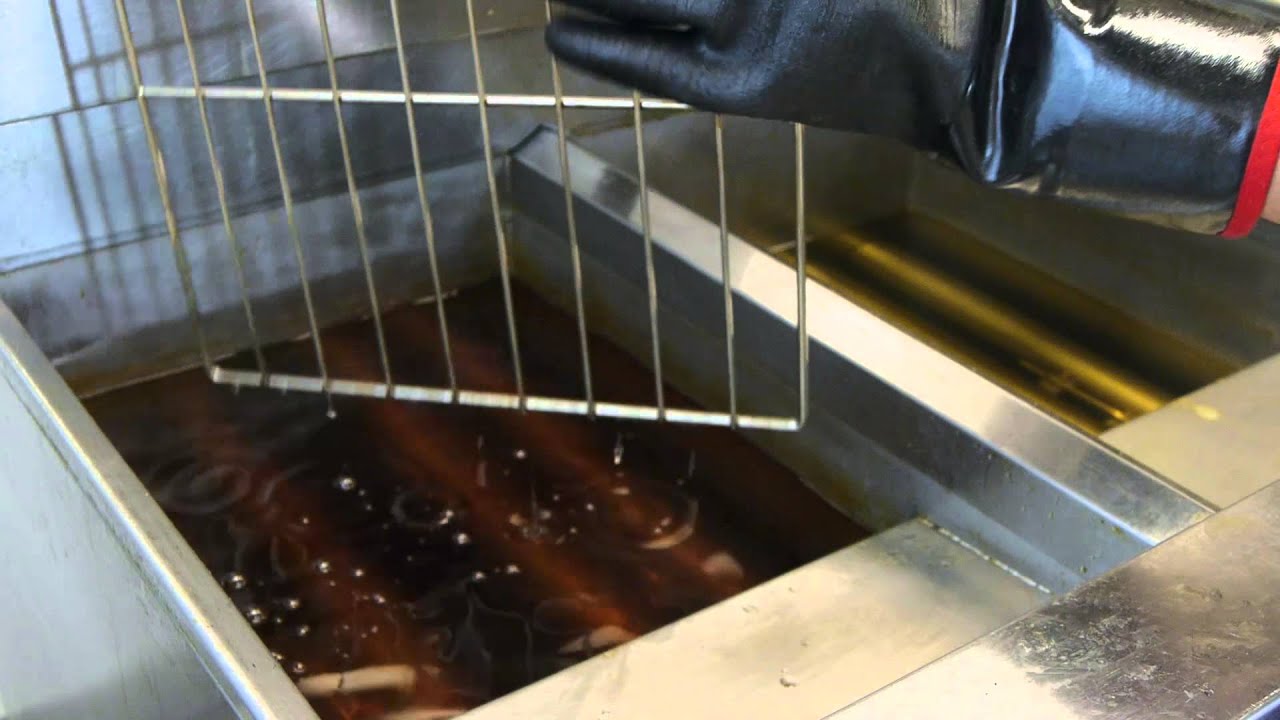

Deep fryer oil filtration is an indispensable process for any high-volume kitchen aiming to maintain food quality and operational efficiency. The primary reason is that over time, cooking oil degrades due to exposure to heat, moisture, air, and food particles. This degradation not only affects the taste and texture of the food but also poses health risks if consumed regularly. Filtration helps extend the life of cooking oil by removing impurities such as crumbs or carbonized bits that accumulate during frying.

Implementing a robust Deep fryer oil filtration system contributes significantly to cost savings for high-volume kitchens. Regularly filtered oil lasts longer than unfiltered oil because it’s cleaner and performs better at higher temperatures without breaking down quickly. By extending the lifespan of cooking oil through filtration processes—whether manual or automated—kitchens can reduce their overall expenditure on this essential commodity.

Moreover, consistently filtered oil ensures that every dish served meets high standards of flavor and presentation—a critical factor in customer satisfaction within competitive culinary markets. When frying with clean oil free from contaminants like burnt residues or old flavors from previously cooked foods, chefs can produce meals with optimal taste profiles that keep patrons coming back for more.